INDUSTRY

At MCL we’re much more than just conveyor manufacturers - we work alongside our system integrator, OEM and automation partners to create tailored end-to-end solutions and back them up with ongoing upgrades and maintenance.

In combination with our collective years of experience and commitment to excellence, we’ve earned a reputation in the market for delivering innovative conveyor solutions that exceed the expectations of our clients. That’s what makes us a trusted partner for enhancing productivity, efficiency, and profitability - no matter your industry.

With MCL as your industrial conveyor partner, you can trust in our ability to deliver custom solutions that meet the exacting requirements of your application.

Learn more about our team to find out how a MCL conveyor solution can help to set you apart from the competition and drive improved logistics performance and production-line outputs. Alternatively, ask your system integrator, OEM or automation lead to specify MCL infeed solutions on your next project.

Trusted industrial conveyor manufacturers

Our dedicated team of engineers, designers and technicians work closely with our integration partners and end-user customers to get a holistic understanding of the often unique challenges and situational requirements that calls for MCL to be involved in the first place, creating robust conveyor system solutions that address the needs of each business environment.

From initial consultation to final installation and after-sales support, we are proud to prioritise customer satisfaction and strive to build long-lasting relationships based on trust, reliability and mutual success.

We take pride in our ability to provide comprehensive solutions that not only meet but exceed the standards of both our industry and yours, setting new benchmarks for performance, durability and cost-effectiveness across the board.

What we do

The movement of goods from place to place utilising various different means.

The collection of various goods with or without pressure in singular or multiple zones.

The classifying and arranging goods based on one or more factors such as size, shape, location, product code or type.

The process of loading boxes, groups of boxes, or layers (usually from a conveyor) onto a pallet or large container.

Innovation within the industry

With a focus on quality, innovation, and continuous improvement, we are constantly evolving and adapting to meet the ever-changing needs of modern industries. Our state-of-the-art conveyor manufacturing facilities, advanced technology and skilled team enable us to stay at the forefront of conveyor design and engineering, offering cutting-edge solutions that address the complex challenges our clients face every day.

Whether you're a small-scale operation or a large multinational corporation, you can rely on MCL and our trusted partners to deliver custom conveyor systems that optimise your processes and drive bottom-line results through improved logistics performance and production outputs.

Industries we service

From fruit and vegetable post grading and manufacturing to logistics and warehousing, MCL serves a diverse range of industries with custom conveyor solutions tailored to their needs. Our extensive experience spans across sectors including automotive, pharmaceuticals, electronics, 3PL and more.

With a deep understanding of the unique challenges and requirements of each sector we service, MCL works closely with clients to develop customised solutions that address their specific needs and objectives.

Whether you're looking to improve throughput, reduce downtime, enhance safety or streamline production in general, MCL has the expertise and resources to deliver conveyor systems that meet your exact specifications and deliver measurable results. Best of all, our solutions are simple to integrate into existing Warehouse Management Systems (WMS), making your job as easy as possible.

Book a free on-site consultation

Reach out now and talk to us about the possibility of booking a free on-site consultation. While on-site, we can talk you through the basics of how our systems will impact your efficiency with no cost to you.What problems do we solve?

IMPROVED BOTTOM LINE

Our custom solutions improve the efficiency of your business by reducing downtime, optimising your existing systems and delivering quality products and ongoing service at a competitive price.

EASY INTEGRATION

We're adept at stepping into an existing supply chain and helping to streamline it by delivering resources on time, every time. We're proud to build relationships as strong as our products.

ONGOING EMERGENCY SUPPORT

From initial consultation to post-installation support, our dedicated team is attentive and on-call for follow-up orders or maintenance needs. We're always available should you need an emergency component.

DESIGN-LED SERVICE

We make it easy for you to get the details on our designs, so you can make informed decisions about them and easily overcome potential functional issues.

Why us?

Highly detailed solutions are specifically designed to meet unique product & logistical needs.

Fast efficient movement of goods, increasing throughput and reducing labour costs.

Vertical Transport Systems transport products between levels, allowing the use of overhead conveyors, which remove obstructions from your floor.

Built to withstand heavy-duty operations and provide long-lasting material handling solutions.

Case Study

MCL Conveyor Construction for T&G Global

- Background

- The original challenge

- The MCL solution

- The end result

- Conclusion

Background

At Modular Conveyors Ltd (MCL), we specialise in the design and manufacture of conveyors and components for the materials handling industry, system integrators, OEMs, automation businesses and their clients. A proud leader in our field, one of our key hallmarks is delivering cutting-edge designs through a partnered approach with all vested parties — ensuring the best outcomes possible and ongoing R.O.I.

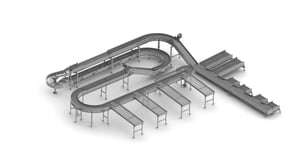

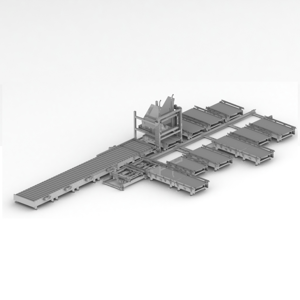

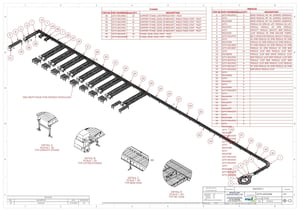

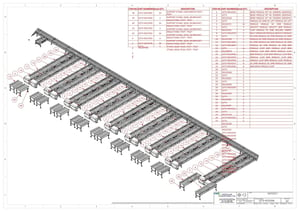

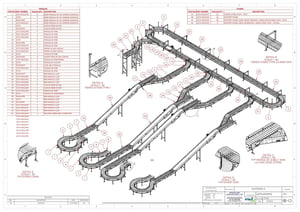

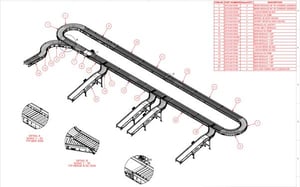

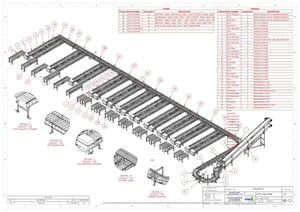

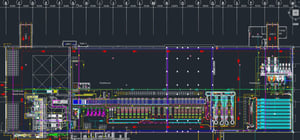

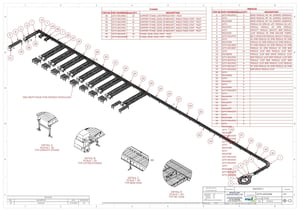

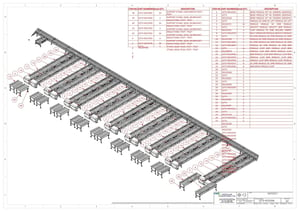

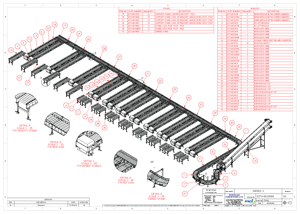

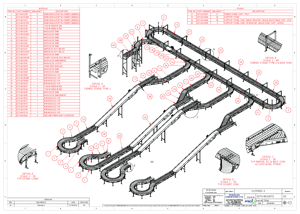

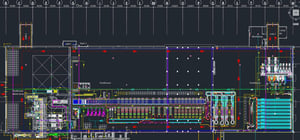

In 2022, we had the privilege of collaborating with T&G Global, a household name in New Zealand and one of the nation’s most iconic produce growers and apple exporters. The system featured various conveyors, and specialist devices — capped off with integrated robotic palletisers for unmatched efficiency. This case study demonstrates how we engaged with and interpreted the system integrator and end-user client needs successfully.

The original challenge

T&G Global needed a comprehensive conveyor system for their food processing plant to improve the movement of produce from grading to packaging. The system needed to plug and play with third-party food grading equipment, carton erectors and robotic palletisers. Time was of the essence, and their initial provider couldn't meet the project's tight deadline.

Faced with this pressing need, T&G Global turned to MCL for our expertise and proven ability to turnaround complex projects. Noting that we were already juggling multiple ongoing projects, we were tasked with designing a system that not only met their immediate needs but was also replicable for future use within the next 12 to 24 months.

The MCL solution

MCL rose to the occasion by delivering a fully customisable and innovative conveyor system tailored to T&G Global's idiosyncrasies—no clearer testament to our ability to prioritise efficiency without ever compromising on quality.

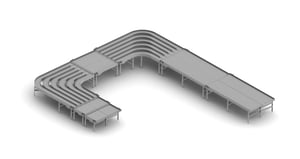

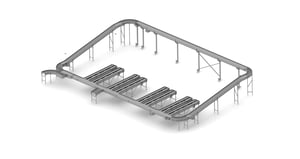

Our engineering team carried out a thorough analysis of T&G Global's operational requirements. Recognising the need for a system that could handle large volumes while maintaining gentle handling of produce, we crafted a modular conveyor system featuring:

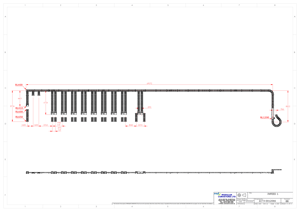

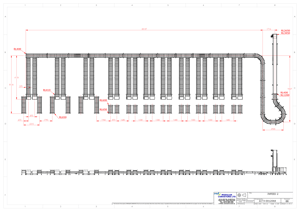

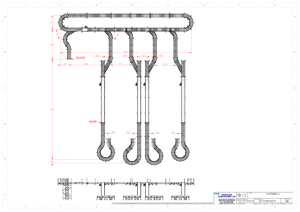

- Transport Conveyors: Over 154.5 metres of Belt Driven Roller (BDR) conveyors were installed to enable efficient and reliable movement of goods across their facility.

- Infeeds and flat belt conveyors: 43 custom-designed infeeds and flat belt conveyors were added to facilitate smooth transitions between different stages of the processing line.

- Advanced motor technology: The inclusion of 24vDC driven rollers provided energy efficiency and precise control, essential for handling easily bruised produce.

- Zinc-plated rollers and pneumatic lift units: These features boosted the durability and flexibility of the system, making adjustments and maintenance much simpler.

- EZQube control cards: State-of-the-art control systems were integrated to provide real-time monitoring and control, creating a conveyor system with better performance overall.

- Integration with third-party systems: The conveyors were designed to work collaboratively with existing food grading equipment, carton erectors, and robotic palletisers, creating operational cohesion.

By honing in on modular design principles, the system allows for easy replication and scalability, allowing T&G Global to roll-out similar conveyor solutions in other facilities within 12 to 24 months.

The end result

MCL's innovative conveyor construction not only met but exceeded T&G Global's expectations. The new system markedly improved throughput slashed manual labour costs and improved the way they utilised space within their existing facility. By adding advanced features like 24vDC driven rollers and EZQube control systems, T&G Global made sure their operations kept pace with their ambitions.

The project's resounding success has positioned T&G Global to replicate the conveyor system in other locations, producing consistent performance across their facilities. Our collaborative approach and solution-focused mindset earned us positive feedback from T&G Global and our project partners, Blue Fruit Design and Optimal Tech.

Conclusion

At MCL, we firmly believe that every challenge is an opportunity to innovate. Our successful partnerships with numerous System Integrators for various Global Brands speaks to our commitment of delivering customised conveyor solutions that meet exacting specifications. No job is too big or too small for us—from a single roller to a fully automated system, we are here to help.

If your business is seeking advanced conveyor solutions that integrate effortlessly with existing systems, we invite you to contact us. With our local expertise and global reach, MCL is your trusted partner.

Custom conveyor builds for all industries

We have the expertise to design and manufacture conveyor systems that deliver optimal performance, reliability and safety. By combining our industry knowledge with advanced engineering and manufacturing capabilities, we provide solutions that address your priorities and help you directly achieve your goals.

We can custom build any type of conveyor, from slat chains to rollers, enabling us to supply both full builds and single parts. Whether you're looking for a conveyor device manufacturer or someone to build a full solution for you, we can help.

Our commitment to excellence, reliability, and customer satisfaction sets us apart as the preferred conveyor manufacturer for use in many industrial conveyor solutions

Custom conveyor design

- Discuss objectives and provide an overview of potential solutions

- Determine the most effective conveyor system layout

- Calculate the belt loading and help select the correct motor and drive

- Ensure you achieve the correct belt speed to meet your throughput requirements

- Integrate your conveyor or conveyor system with other equipment

Deal with the custom conveyor solution specialists

At MCL, we believe in a collaborative approach for our conveyor system design. From initial concept to final implementation, our team of experts works closely with you to develop a solution that aligns with your vision and business objectives.

Our comprehensive design process includes feasibility studies, 3D modelling and prototype testing to ensure optimal functionality and efficiency of your new or upgraded conveyor system. With MCL by your side, you’ll know your project is in safe hands from start to finish.

Learn more about our specific design services.

Frequently Asked Questions

Conveyors are utilised across a wide range of industries, including manufacturing, food and beverage processing, packaging, pharmaceuticals, logistics, and more. Any industry that requires the movement of goods or materials within a workspace can benefit from conveyor systems.

Get In Touch

No matter the industry or application, MCL's conveyor systems are always engineered for performance, reliability and efficiency. With our customisable solutions and expert support, we help businesses achieve their goals and cut costs while they do it.

Experience the difference with MCL - a cost-effective and efficient solution for all your conveyor needs. Contact us today to discover how we can elevate your business to new heights with our custom conveyor solutions.