TRANSFERS

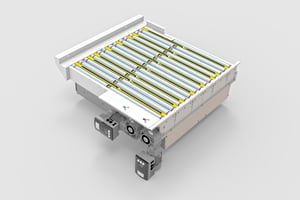

Conveyor transfers are an important part of building your ideal conveyor system, regardless of what industry you’re in. They can be vital for warehouse layout, building production lines, packaging systems, or improving existing material handling solutions.

As a leading provider of modular conveyor systems in New Zealand, we understand that efficient material handling is critical to the success of many businesses.

Our conveyor transfer systems are designed to integrate easily with your operation, optimise your workflow and maximise your productivity, ensuring smooth material flow throughout your facility. If you need conveyor transfer solutions, you’ve come to the right place.

Are conveyor transfer systems right for my business?

MCL has spent years perfecting the precision engineering required to create reliable conveyor-to-conveyor transfer solutions. After all, conveyor systems are supposed to improve productivity for you and avoid bottlenecks: When you need to transfer objects from one conveyor to another, you don’t want your system to fall apart.

Transfer systems can deliver multiple benefits such as separation, sortation, increasing product flow and maximising efficiency. They can also be used to make sure carton orientations are always correct for label printing, barcode scanning, and other similar vital workflow steps.

Our solutions can also be custom-built for brand new layouts, and tailored to your exact specifications. This means they’re also a good fit for you if you’re designing a new conveyor system from the ground up, and it requires multiple conveyors that need to transfer objects between them.

Key problems regarding conveyor transfers

The physics of conveyor systems can be deceiving - transferring an object from one conveyor to another requires an understanding of the common pitfalls that may trap an object, and these depend entirely on exactly what materials you need to handle.

As experts in creating conveyor systems, we can help you install or improve your conveyor transfer systems, either eliminating points where a transfer is failing, or creating a reliable transfer point that won’t create bottlenecks in your system.

Benefits of conveyor transfer systems

- Efficiency: By streamlining material flow and minimising congestion, our conveyor transfer systems improve operational efficiency and productivity.

- Flexibility: With customisable design options, our conveyor transfer systems can be tailored to meet your specific needs and adapt to changing operational requirements.

- Reliability: Built with high-quality materials and precision engineering, our conveyor transfer systems are durable and built to last.

- Cost-effectiveness: By minimising bottlenecks, our conveyor transfer systems offer a cost-effective way of achieving your material handling needs.

Why us?

We offer competitive pricing without cutting corners on build quality, ensuring that you get the best return for your investment.

With years of experience behind our streamlined processes and expert project management team, we can get your system up and running in no time.

We use rigorous quality control for every step of our build and install phases, delivering conveyor systems that meet our exacting standards for quality.

We aim to build long term partnerships to ensure your conveyor system operates smoothly for years to come, with continuous support and maintenance.

Book a free on-site consultation

Reach out now and talk to us about the possibility of booking a free on-site consultation. While on-site, we can talk you through the basics of how our systems will impact your efficiency with no cost to you.Conveyor transfer features

Our conveyor transfer systems are designed with a range of innovative features to optimise performance, reliability, and efficiency.

From precision-engineered components to a variety of design options, our conveyor transfer systems can easily be adapted to meet the exact needs of your business.

Conveyor transfers to suit your needs

Whether you need a simple transfer system or a complex network of conveyor transfers, we have the expertise and resources to deliver a solution that not only meets your needs but exceeds your expectations.

Thanks to our tailored approach, our transfer conveyors can accommodate many different variables, such as angles, drive types, and belt widths. This makes them ideal whether you need them to integrate with an existing system, or you’re looking to create a new system from scratch.

%20TIMING%20BELT%20TRANSFER.jpg?width=300&name=(31)%20TIMING%20BELT%20TRANSFER.jpg)

Custom conveyor design

- Discuss objectives and provide an overview of potential solutions.

- Determine the most effective conveyor system layout.

- Calculate the belt loading and help select the correct motor and drive.

- Ensure you achieve the correct belt speed to meet your throughput requirements.

- Integrate your conveyor or conveyor system with other equipment.

%20DCRB%20MODULE%20WITH%2090%20DIVERT%20AND%20A%20SMALL%20SECTION%20RECEIVING.jpg?width=300&name=(2)%20DCRB%20MODULE%20WITH%2090%20DIVERT%20AND%20A%20SMALL%20SECTION%20RECEIVING.jpg)

Ongoing Deliverability & Support

At MCL we treat our clients as extensions of our own team, because your success is our success. We always offer comprehensive after-sales services, including continuous improvements to guarantee your long-term success. These upgrades are designed to integrate seamlessly with previous versions of our products, ensuring compatibility with your existing workflow.

For more details, ask about our Preventative Maintenance Scheduling (PMS), and we can help you eliminate downtime and stay ahead of all the necessary upkeep.

We value building trust with our partners with reliable delivery times and quick support for emergencies. With MCL, you can trust that your investment isn't just a product, it's a partnership.

Get a free quote

Looking for better material handling systems with easy integration? Get a free quote today and discover tailored conveyor solutions for your business with MCL.

Frequently Asked Questions

A conveyor transfer smoothly moves materials from one conveyor to another, often when there's a change in direction or elevation.

Transfers come in various forms and may be one unit or integrated into a conveyor module dependent on the application, space available or transfer rate or path required.

Product transfer between conveyors is vital for maintaining continuous material flow during production or distribution. Using mechanisms like transfer plates, diverters, pushers and more, products are redirected or guided from one conveyor to another.

Smooth transitions between conveyors are crucial for preventing product damage and maintaining optimal material flow. Factors like conveyor speed, product size and belt alignment need to be carefully considered ensuring seamless transitions and maximising efficiency.

Get In Touch

No matter the industry or application, MCL's conveyor systems are always engineered for performance, reliability and efficiency. With our customisable solutions and expert support, we help businesses achieve their goals and cut costs while they do it.

Experience the difference with MCL - a cost-effective and efficient solution for all your conveyor needs. Contact us today to discover how we can elevate your business to new heights with our custom conveyor solutions.